The purpose by Scientific Injection Molding

1,Verify the mold production function by the objective injection molding and make sure it can produce qualified samples and have stable mass production.

2,Follow the steps to adjust the molding parameters in the scientific way and have reliable evidences for the parameters adjustment.

3,Making the database for all the process parameter and leading the latest producers use the molding conditions and data directly.

4,Evaluating the best cycle time and the most stable molding condition.

5,Reducing the time for readjusting the machine process parameter when the machine is transferred.

6,Make sure to provide customers 100% high qualified plastic parts without hand selection.

Testing item

1,Empty running test

2,Water flow test

3,Test for actual mold temperature and actual material temperature

4,The preliminary confirmation of plastic parts cosmetic and flow front balance

5,The material viscosity test (the optimum injection speed test)

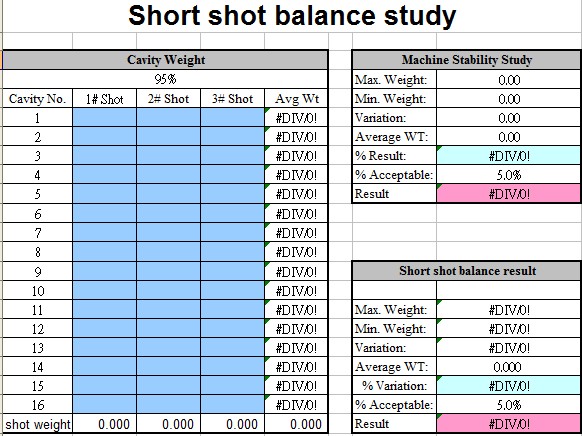

6,Test for plastic parts water flow balance

7,Plastic parts flow analysis and packing test

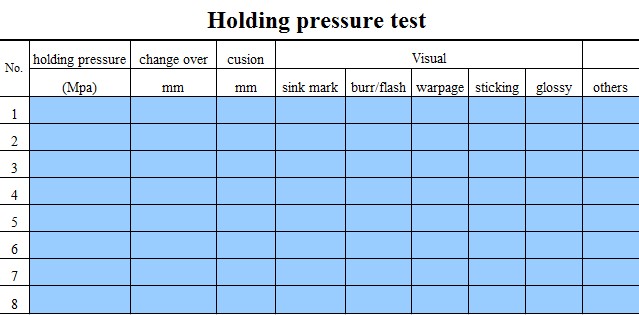

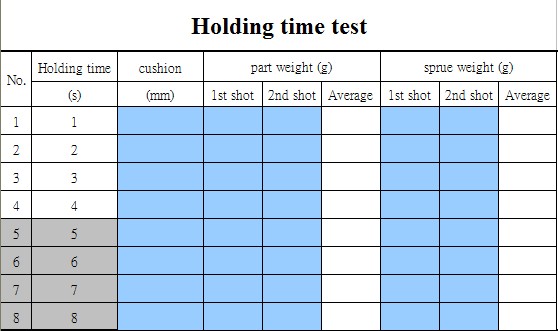

8,Plastic parts packing time test

9,Minimum clamping force test

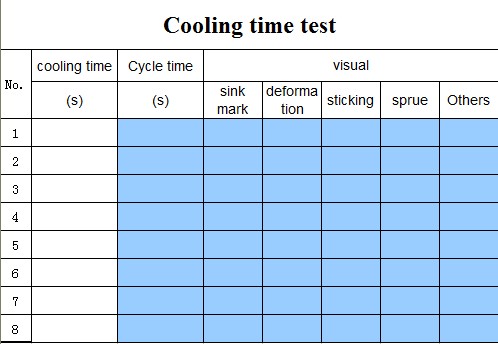

10,Optimizing cycle time